The "model" factory

A comprehensive view of advanced digital technologies for the manufacturing industry, useful for large, small and medium-sized enterprises.

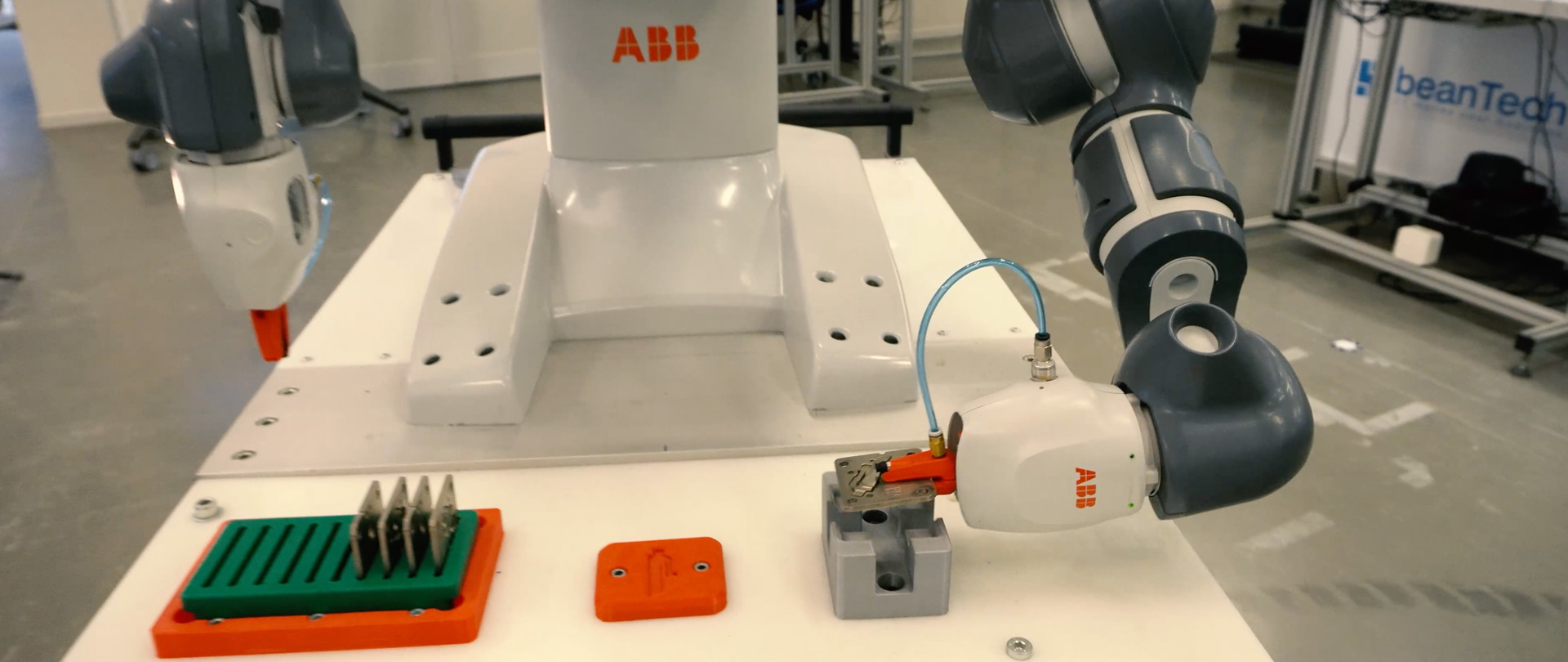

An actual 4.0 smart factory has been installed in the demonstrator. Machinery, warehouse management, assembly and test lines, office space: here you can discover integrated digital solutions for all business areas and see the benefits first-hand.

Reproducible tests in the Living Lab

Reproducible tests in the Living Lab

- Pick to Light for order preparation without paper documents and hands-free.

- Visual Recognition to automatically recognize shapes and products.

- Collaborative robots for COBOT production.

- AGV, that is to say automated, unmanned vehicles for transportation in the warehouse.

- Digital Twin: product and process integration.

- Purchasing automation incorporating various procurement functions.

- Development of Smart Products.

- Office Automation to automate and speed up office tasks and procedures.

- Robot-based process automation.

- Mixed and augmented reality for standard operating procedures.

- Construction 4.0, such as Building Information Modeling - BIM - and Real Time Tracking of workers and equipment.

Benefits for businesses

- Improving production quality by reducing processing waste and false positives.

- Raising production efficiency by reducing downtime and rework times.

- Reducing maintenance costs by employing predictive maintenance supported by data analytics.

- Improving after-sales service with remote customer support solutions.

IP4FVG's Living Labs

The IP4FVG

living LABS

Book a visit with our experts, come and try the technological solutions present in the demonstrators.